AwiHome – Awite to be 100% self-sufficient in 2023

We already reported on our in-house AwiHome project in AwiGossip II / 2023. And of course we continued as promised, so here some sunny information in the less sunny season.

We are gradually moving our vehicle fleet towards alternative fuels. (Unfortunately, the choice of gaspowered vehicles is very limited). We now have five fully electric vehicles, one gas-powered vehicle and three hybrid vehicles, and still counting. We hope to be able follow this path for service vehicles as well in the near future. After expanding our supply point, we have now extended our in-house charging points to six. Everything is visualised and can also be viewed, adjusted and used via an Awite app. As we are not only concerned with vehicles, but are also very happy when our colleagues are physically active, our new e-supply point also has weatherproof bicycle parking spaces, a small bicycle workshop with repair facilities, and charging facilities for e-bikes. In recent months, we have also expanded our battery storage capacity by 50% in order to come closer to our goal of making our building and production energy self-sufficient. We are proud of the final result for 2023! Awite worked, developed and produced 100% self-sufficiently at the company headquarters in 2023. We were also completely self-sufficient 57% of the time, without any external electricity supply. And we even generated an electricity surplus that enabled us to drive another 25,000 km with electric vehicles powered by our own electricity. It goes without saying that every kWh we purchase is green electricity.

And what’s next? 100% self-sufficient, at all times. When???

Biogas and biomethane plant of the Benas Power Group in Ottersberg

On 26 September, the gas analysis system with the project number 4240 went into service for Mr. Heitmann at the Benas Power Group biogas and biomethane plant in Ottersberg. The plant is flexible to over 4 MWel and relies on a proven substrate mix. This includes silage maize, grass silage and dry chicken manure (HTK). The AwiFLEX XL monitors the biology and the spaces between the seven double membrane gas storage units (TRAS 120). With 13 measuring points and six sensors (CH4, CO2, O2, 2* H2S and H2), the gas analysis system is well-equipped to monitor the entire plant. The external measuring point switch-over AwiSamplex makes this large number of measuring points possible. The long distances of the measuring gas lines (>100m) between the installation site of the analysis system and the blow-out units of the double membrane gas storage units are bridged by the amplifier pump AwiVac. The entire process is now automatically monitored and documented.

Thanks to the selection of a second H2S sensor with a smaller measuring range of 0…200ppm, the activated carbon filter can be reliably monitored for a breakthrough. At the upstream measuring points, the higher H2S concentrations (HTK) are taken into account with a measuring range of 0…1,500ppm. The AwiFLOW gas flow sensor enables the Benas Power Group to reliably document the gas quantities produced.

We would like to thank Mr Heitmann for this cooperation and wish this advanced, sustainable plant ‘full power’ for the future.

The Wind of Change

JBS S. A. operates a lagoon biogas plant near the Brazilian city of Ituiutaba using waste water and residues from a neighbouring slaughterhouse. The methane-rich biogas (>65% CH4) is converted into renewable electricity in a combined heat and power plant (CHP).

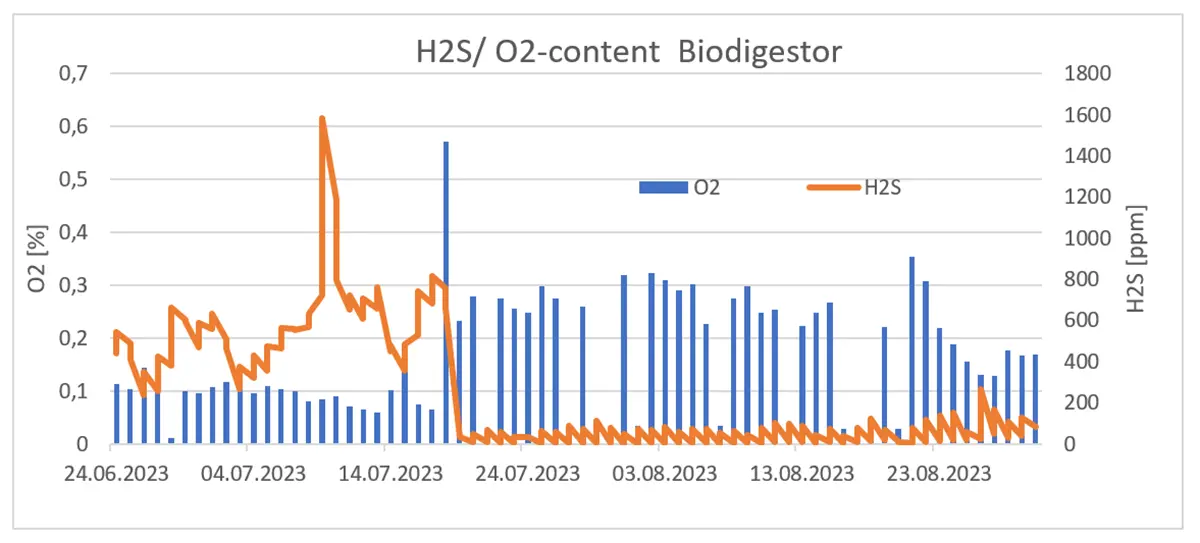

Although the input materials provide a lot of energy, the high protein content and the resulting H2S concentrations (>1,500 ppm) place special demands on the desulphurisation of the biogas. Biological desulphurisation is used in Ituiutaba, i.e. the interaction of special bacteria that convert H2S with O2 from the air to elemental sulphur. The desulphurisation performance of the bacteria depends on various factors such as process temperature, retention time, existing colonisation areas, etc. and therefore has a fluctuating O2 demand over time. To achieve optimum desulphurisation performance, the AwiDESULF has been providing a breath of fresh air since mid-July. With two compressors for air supply, the control parameters H2S and O2 (measured values from the AwiFLEX) and fuzzy logic, the optimum operating point for air injection is determined and maintained fully automatically. As additional process parameters, the AwiFLEX measures the CH4 and CO2 content.

The progression of the H2S and O2 concentrations in the diagram shows the levelling of the air injection after the installation on 18 July. This enabled the average H2S concentration to be reduced from 570 ppm to 50 ppm thanks to the smart use of air. We would like to thank JBS S.A. for the interesting project and the good cooperation and are looking forward to further projects.

We would like to thank JBS S. A. and our customer BRG Geradores S.A. for the interesting project, the good co-operation and look forward to further projects.