AwiHome - Renewable and sustainable also in production and at work

Renewable is what drives us, day after day. That’s why we don’t want to limit ourselves to manufacturing gas analysis systems for renewable applications, but also want to implement sustainability more and more in our production.

What have we done since the beginning of 2022 to improve the step towards energy self-sufficient, modern and sustainable production?

- Switching to LED lamps and thus saving > 10 % of our energy consumption.

- Saving packaging material and delivery traffic by using used cardboard boxes as packaging material.

- Equipping our building with contacts for windows and doors, locking systems, smoke and fire detectors, CO monitoring in meeting rooms.

- Extension of our grid connection and expansion of our PV system from 25 kWp to 68 kWp – commissioning in November 2022.

- Installation of a 44 kWh energy storage unit.

- Installation of a high-tech weather station for better data and forecasts – for the future.

- Installation of an info touch screen with current consumption and generation, as well as an app, so that all colleagues can follow along.

And what comes next? We are continuing in the direction of e-mobility with a small e-supply point for bicycles, additional wall boxes for e-vehicles and want to make our energy management, storage and charging processes forward-looking and intelligent this year. Energy meters will help to identify further savings potentials and our heating system (which has of course been running on a brine heat pump for 13 years) is also to be brought up to scratch.

And then we’re sure to have the next ideas, let us surprise you.

MULTI-TALENT - BIOMETHANE

Biogas is the all-rounder among renewable energies. Biogas can be used to provide electricity, heat, fuel and platform chemicals. This versatility makes biogas unique among renewable energies. In particular, upgrading biogas to biomethan and feeding it into the natural gas grid is a promising use path for transforming the energy system. Many governments around the world have recognised this and are expanding their biogas upgrading capacities.

We are pleased that we can support this development with our individual solutions (read article below + Biogastreatment).

Biomethane projects

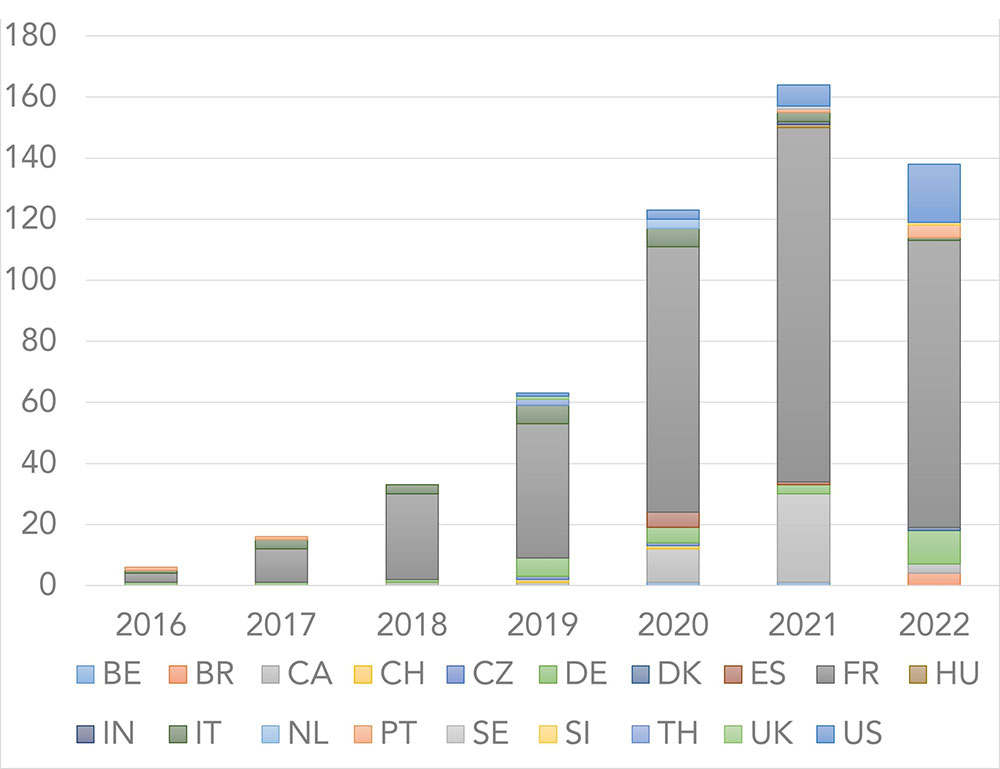

In the last 7 years, we have implemented over 500 biomethane projects on 4 continents and in 19 countries (see chart).

We would like to thank our customers and partners for the good cooperation and look forward to further exciting projects around the Multitalent biogas.

The good in the pot the bad in the jar

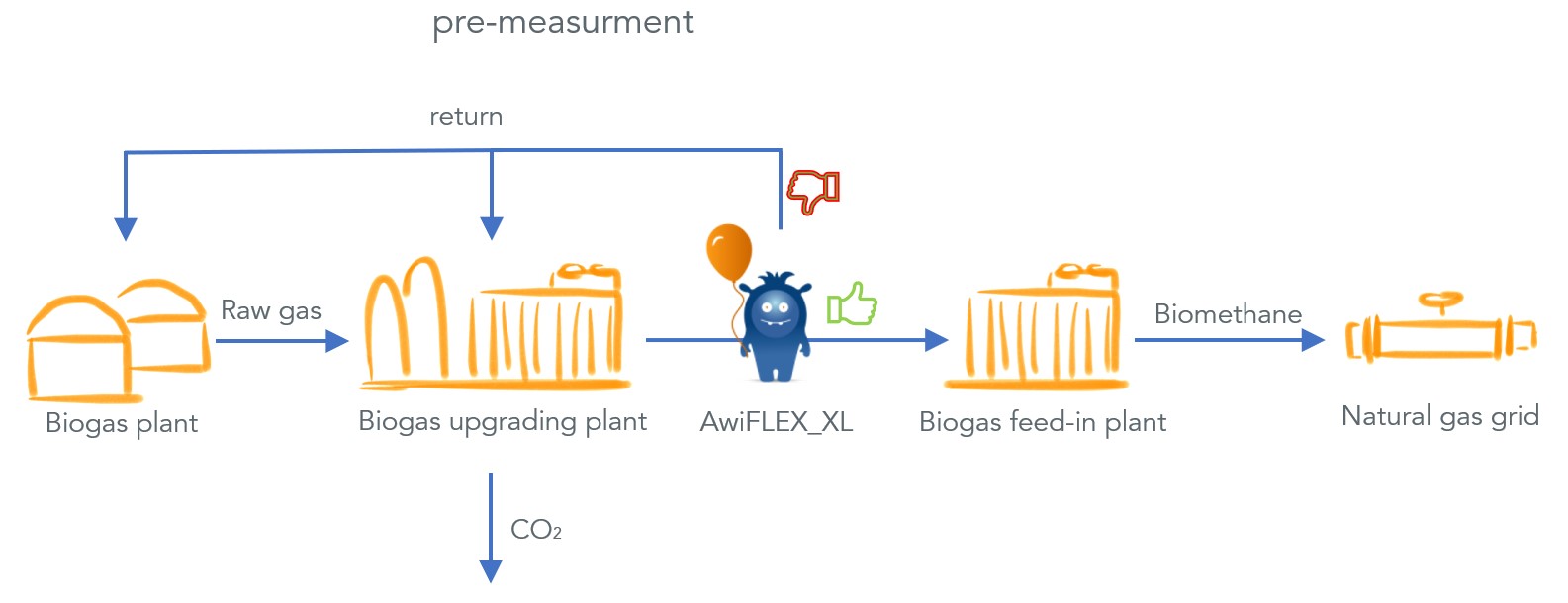

The fairy tale of Cinderella can also be applied to the feed-in of biomethane in the projects of EWE Netz GMBH. Whether it goes into the pot or the potty is decided by the pre-measurement (see diagram).

The heart of the system is an AwiFLEX XL with continuous CH4 and CO2 measurement. In parallel, two alternating sensors measure H2S discontinuously with a measuring interval of 15 min after the biogas upgrading plant. In addition, the dew point and other operating measurements are taken during the pre-measurement. The measurements ensure that the biomethane quality is monitored without interruption upstream of the biogas injection plant. If the quality of the upgraded biomethane is not sufficient, it is returned to the biogas upgrading plant or to the biogas plant and can be upgraded again.

The measurements are used to control if biomethane is outside the required transfer parameters, so that it can be treated again and does not have to be burnt via a gas flare. This prevents the network operator from “shutting down” the biogas feed-in plant due to poor gas quality and possibly having to flush it out and start it up again. This means that no biomethane outside the required parameters is fed into the natural gas grid.

The AwiFLEX XL monitors itself through automatic calibration of all installed sensors. This ensures that the low measurement uncertainties (CH4 0.03 %; CO2 0.004 %; H2S 0.5 ppm) are permanently maintained and process reliability is increased.

Thus, the gas analysis system is an important component for the permanent monitoring of the entire process chain and in the future no more bad ones will end up in the potty.

We would like to thank EWE Netz GMBH for the exciting projects and look forward to further cooperation.

Upcoming Events

EUBCE - Bologna

05. – 08.06.2023

Nordd. Biogas-Branchentreff - Rendsburg

21.09.2023

Ecomondo - Rimini

07. - 10.11.2023

Biogas Convention & Trade Fair

12. - 14.12.2023